Detalium

Series SILIKE Si-TPV 2150 est elastomer dynamicus e silicone vulcanizato fundatus, elaboratus technologia compatibilitatis provecta. Hic processus siliconem gummi in SEBS dispergit ut particulas minutas, ab 1 ad 3 micron sub microscopio. Hae materiae singulares robur, tenacitatem, et resistentiam abrasionis elastomerorum thermoplasticorum cum proprietatibus desiderabilibus siliconei, ut mollitiem, tactum sericum, et resistentiam contra lucem ultraviolaceam et chemica, coniungunt. Praeterea, materiae Si-TPV sunt recyclabiles et in processibus fabricationis traditis iterum adhiberi possunt.

Si-TPV directe ut materia rudis adhiberi potest, specialiter designatum ad applicationes super-formationis mollis tactus in electronicis induendis, involucris protectoriis pro instrumentis electronicis, componentibus autocineticis, TPE summae qualitatis, et industriis filorum TPE.

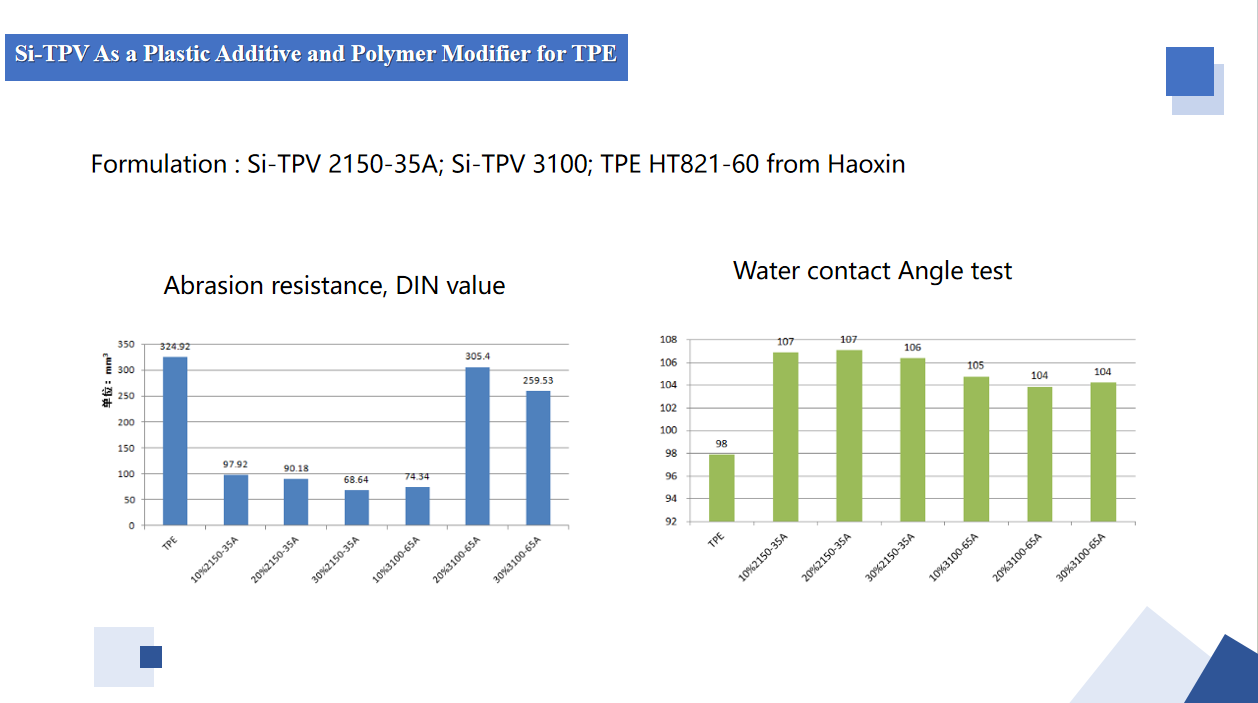

Praeter usum directum, Si-TPV etiam ut modificator polymerorum et additivus processus pro elastomeris thermoplasticis vel aliis polymeris fungi potest. Elasticitatem auget, processum emendat, et proprietates superficiales amplificat. Cum TPE vel TPU mixtum, Si-TPV superficiem diuturnam levitatem et sensum tactilem iucundum praebet, simul resistentiam scalpturae et abrasionis augens. Duritiem minuit sine negative afficiendo proprietates mechanicas et meliorem resistentiam senescentiae, flavescentiae, et macularum offert. Etiam aspectum opacum desiderabilem in superficie creare potest.

Dissimilis additivis siliconicis usitatis, Si-TPV in forma granulorum praebetur et instar thermoplastici tractatur. Per matricem polymericam subtiliter et homogenee dispergitur, copolymero matrici physice adhaerente. Hoc curam migrationis vel "florescentiae" eliminat, Si-TPV solutionem efficientem et innovativam ad superficies molles et sericeas in elastomeris thermoplasticis vel aliis polymeris obtinendas reddit, nec gradus processus vel obductionis additionales requirit.

Commoda Clavia

- In TPE

- 1. Resistentia abrasionis

- 2. Resistentia macularum cum angulo contactus aquae minore

- 3. Duritiem minue

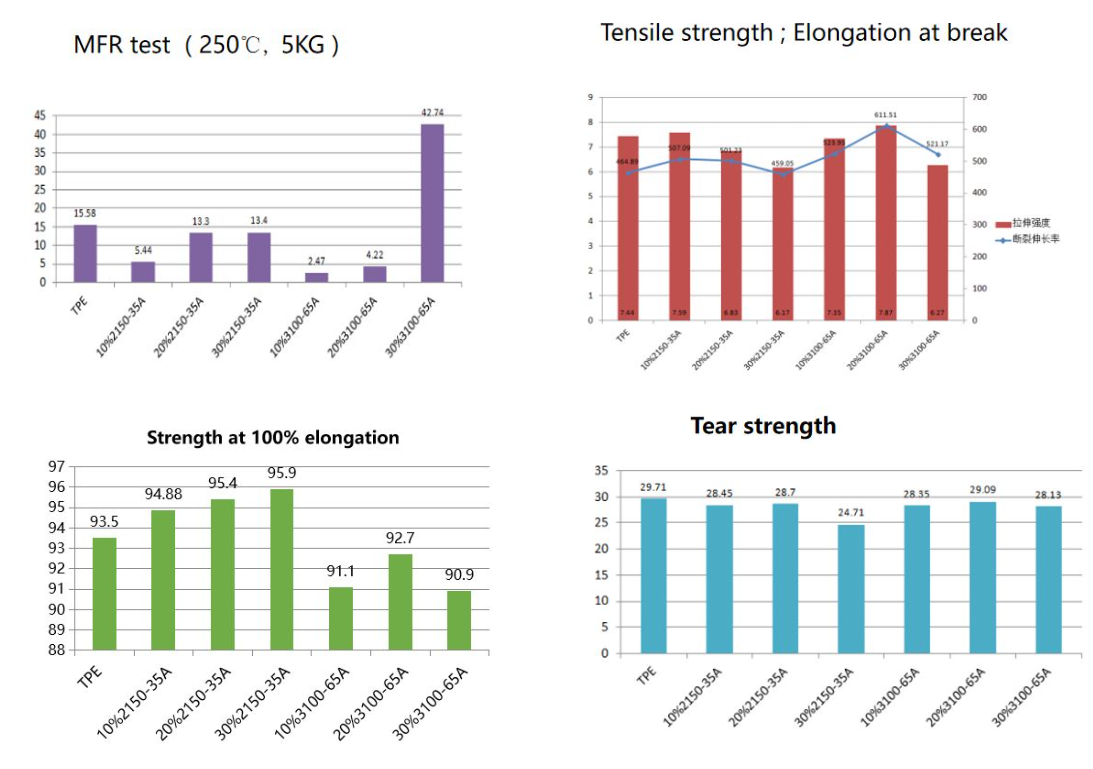

- 4. Paene nulla afficiuntur proprietates mechanicas cum serie nostra Si-TPV 2150.

- 5. Haptica optima, tactus siccus et sericus, nulla efflorescentia post usum diuturnum

Durabilitas Sustentabilitas

- Technologia provecta sine solvente, sine plastificante, sine oleo emolliente, et inodora.

- Protectio naturae et facultas redivivae rerum.

- In formulis legibus congruentibus praesto.

Studia Casuum Additivi Plastici et Modificatoris Polymeri Si-TPV

Series Si-TPV 2150 proprietates habet tactus mollis diuturnus cum cute, bonae resistentiae maculis, nullius plastificantis et emollientis additi, et nullae praecipitationis post usum diuturnum, quae ut additivum plasticum et modificans polymerorum inservit, praesertim apte ad praeparationem elastomerorum thermoplasticorum tactu sericeo iucundo adhibenda.

Comparatio Effectuum Additivi Plastici Si-TPV et Modificatoris Polymeri in Efficacia TPE

Applicatio

Si-TPV agit ut modificator tactus et additivum processus pro elastomeris thermoplasticis aliisque polymeris. Cum variis elastomeris et materiis plasticis machinalibus vel generalibus, ut TPE, TPU, SEBS, PP, PE, COPE, EVA, ABS, et PVC, misceri potest. Hae solutiones adiuvant ad efficientiam processus augendam et ad resistentiam abrasionis et scalpturae partium perfectarum emendandam.

Commodum magnum productorum e mixturis TPE et Si-TPV factorum est creatio superficiei mollis et sericeae, tactus non glutinosus—praese experientia tactilis quam usores finales exspectant ab rebus quas frequenter tangunt vel gerunt. Haec proprietas singularis amplitudinem applicationum potentialium pro materiis elastomericis TPE per multas industrias amplificat. Praeterea, incorporatio Si-TPV ut modificatoris flexibilitatem, elasticitatem, et firmitatem materiarum elastomericarum auget, dum processum fabricationis magis sumptuosum reddit.

Solutiones:

Difficultatem habes ad augendam efficaciam TPE? Additiva plastica Si-TPV et modificatores polymerorum responsum praebent.

Introductio ad TPEs

Elastomera thermoplastica (TPE) secundum compositionem chemicam digeruntur, inter quae sunt Olefina Thermoplastica (TPE-O), Composita Styrenica (TPE-S), Vulcanizata Thermoplastica (TPE-V), Polyurethana (TPE-U), Copolyestera (COPE), et Copolyamida (COPA). Dum polyurethana et copolyestera fortasse nimis elaborata sunt ad quosdam usus, optiones magis sumptuosae, ut TPE-S et TPE-V, saepe aptiorem applicationum formam offerunt.

TPE conventionales sunt mixturae physicae gummi et thermoplasticarum, sed TPE-V differunt particulis gummi partim vel plene conexis, quae earum efficaciam emendant. TPE-V habent compressionem deficientem inferiorem, resistentiam chemicam et abrasionis meliorem, et stabilitatem temperaturae maiorem, quae eas ideales reddunt ad gummi in sigillis substituendum. Contra, TPE conventionales maiorem flexibilitatem formulae, maiorem vim tensilem, elasticitatem, et colorabilitatem praebent, quae eas aptas reddunt ad res ut bona consumptibilia, electronica, et instrumenta medica. Etiam bene adhaerent substratis rigidis ut PC, ABS, HIPS, et Nylon, quod utile est ad applicationes mollis tactus.

Difficultates cum TPE

TPE elasticitatem cum robore mechanico et tractabilitate coniungunt, ita ut sint valde versatiles. Proprietates earum elasticae, ut compressio et elongatio, ex phase elastomerica oriuntur, dum robur tensile et scissurum ex componente plastica pendent.

TPEs sicut thermoplastica vulgaria ad temperaturas elevatas tractari possunt, ubi in phasem liquefactam ingrediuntur, quod efficit fabricationem permittit utens apparatu normali ad plastica tractanda. Eorum amplitudo temperaturae operandi etiam notabilis est, extensa a temperaturis infimis — prope punctum transitionis vitreae phasis elastomeri — ad temperaturas altas prope punctum liquefactionis phasis thermoplasticae — quod versatilitati eorum auget.

Attamen, his commodis non obstantibus, nonnullae difficultates in optima efficacia TPEorum manent. Una quaestio maior est difficultas in aequilibrando elasticitate cum robore mechanico. Augmentatio unius proprietatis saepe alterius detrimento fit, ita ut fabricatoribus difficile sit formulas TPE evolvere quae aequilibrium constans inter desideratas proprietates servant. Praeterea, TPEa obnoxia sunt damnis superficialibus, ut scalpturis et deformationibus, quae negative afficere possunt et aspectum et functionem productorum ex his materiis factorum.