Detalium

Series Si-TPV 2250 SILIKE est elastomer dynamicus vulcanizatus thermoplasticus e silicone fundatus, ad materias spumantes EVA amplificandas destinatus. Series Si-TPV 2250 producitur utens technologia speciali quae efficit ut gummi siliconeus aequaliter in EVA dispergatur ut particulae 1-3 micron. Hic modificator singularis pro materia spumante EVA coniungit robur, tenacitatem, et resistentiam abrasionis elastomerorum thermoplasticorum cum proprietatibus desiderabilibus siliconei, inter quas mollitia, tactus sericus, resistentia UV, et resistentia chemica. Reciclari et iterum adhiberi potest in processibus fabricationis traditis.

Materiae Si-TPV seriei 2250, quae oecologice amicae sunt et molliter tangendum, maxime congruunt cum ethyleno-vinylacetato (EVA) et funguntur ut modificator siliconis novus ad spumam EVA faciendam, cum solutionibus ad emendandas materias spumae EVA in applicationibus ut soleis calceorum, productis sanitariis, productis otii athletici, tapetibus pavimenti, tapetibus yogae, et pluribus.

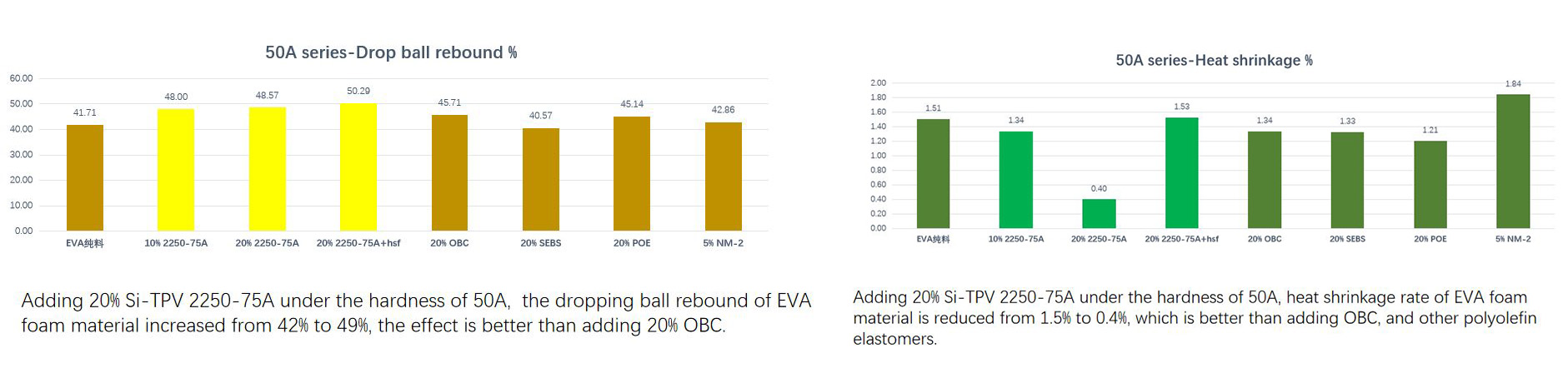

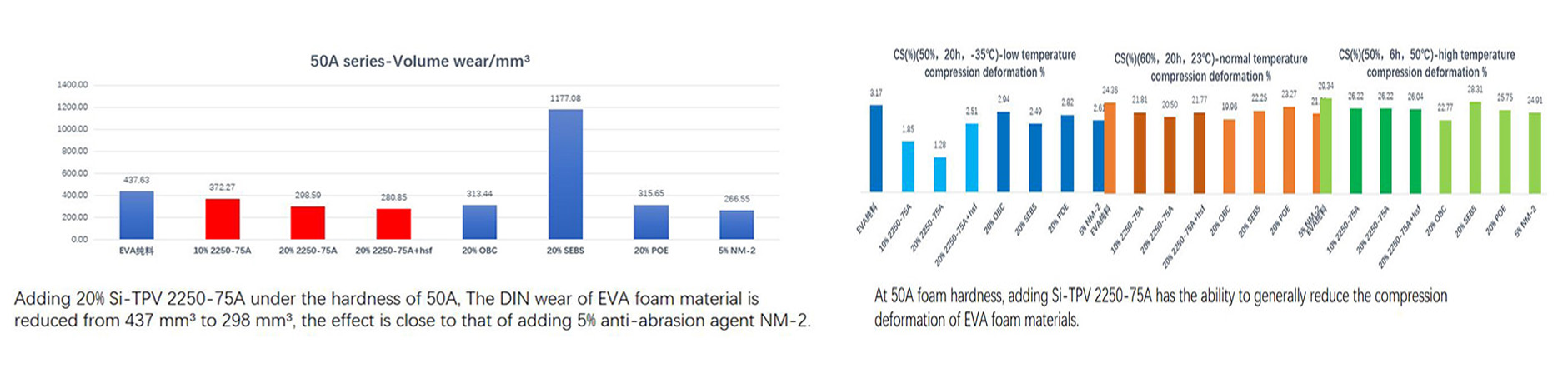

Collatum cum OBC et POE, Highlight compressionem et contractionem caloris in spuma EVA minuit, elasticitatem et mollitiem spumae EVA auget, resistentiam contra lapsum et contra abrasionem amplificat, et detritio DIN a 580 mm3 ad 179 mm3 reducitur atque saturationem coloris in spuma EVA emendat.

Quae efficaces solutiones materiae spumae Eva mollis flexibilis probatae sunt.

Commoda Clavia

Durabilitas Sustentabilitas

- Technologia provecta sine solvente, sine plastificante, sine oleo emolliente, et inodora.

- Protectio naturae et facultas redivivae rerum.

- In formulis legibus congruentibus praesto.

Modificator Si-TPV ad Spumam EVA Studia Casuum

Series Si-TPV 2250 tactum mollem diuturnum cuti benignum, bonam resistentiam maculis praebet, nec additionem plastificantium vel emollientium requirit. Praecipitationem etiam post usum diuturnum impedit. Ut modificator spumae EVA mollis valde compatibilis et novus, praecipue aptus est ad praeparationem materiarum spumantium EVA levissimarum, valde elasticarum, et oecologicarum.

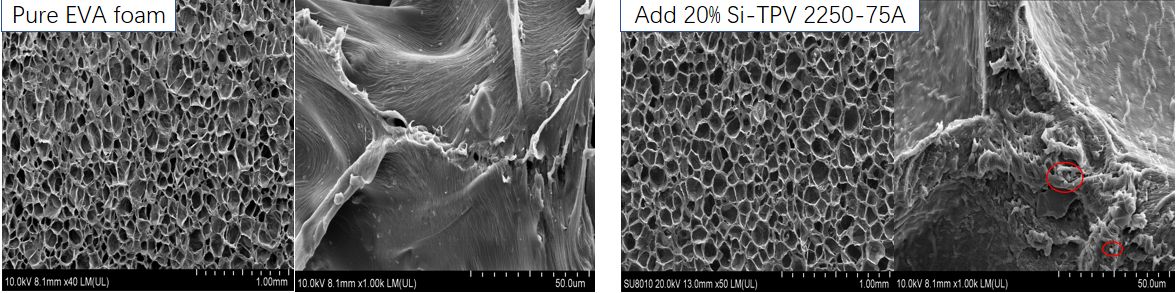

Post additionem Si-TPV 2250-75A, densitas cellularum bullarum spumae EVA paulum minuitur, paries bullarum crassescit, et Si-TPV in pariete bullarum dispergitur, paries bullarum asper fit.

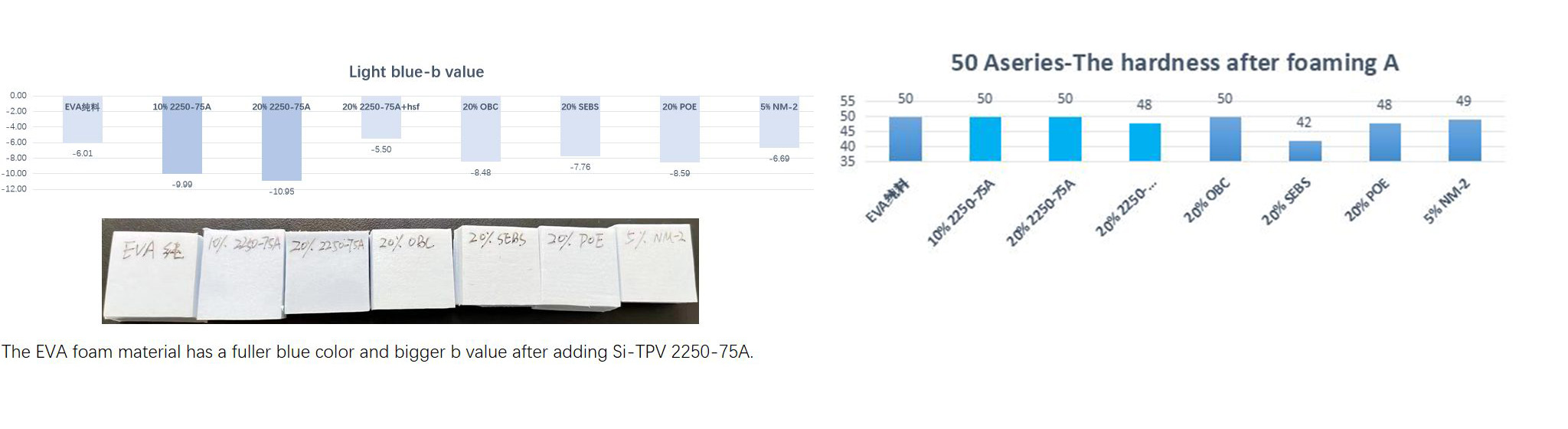

Comparatio Si-TPV2250-75A et effectus additionis elastomeri polyolefini in spuma EVA

Applicatio

Novus modificator Si-TPV viridis et ecologicus, materiam spumosam EVA potentians, quae varias industrias productorum vitae quotidianae et actionum commercialium reformavit, ut calceamenta, producta sanitaria, pulvinaria balneorum, producta otii athletici, stragula pavimenti/yogae, ludibria, involucra, instrumenta medica, apparatum tutelae, producta aquae non labendi, et tabulae photovoltaicae...

Si solutiones spumationis supercriticae tibi curae sunt, nescimus an tibi apta sit, sed haec technologia spumationis chemicae modificatrix Si-TPV, fabricatoribus spumationis EVA, via alternativa esse potest ad res leves et flexibiles cum dimensionibus exactis creandas.

Solutiones:

Spumae EVA Augentes: Solvendo Difficultates Spumae EVA cum Modificatoribus Si-TPV

1. Introductio ad Materias Spumae EVA

Spumae EVA genus spumae cellulis clausis sunt, quae ex mixtura copolymerorum ethyleni et acetatis vinylis producta est, polyethyleno variisque agentibus spumantis et catalysatoribus in fabricatione additis. Clara ob excellentem mollitiem, absorptionem ictus, et resistentiam aquae, spuma EVA structuram levem sed durabilem habet, quae optimam insulationem thermalem praebet. Proprietates eius insignes spumam EVA materiam versatilem faciunt, late adhibitam tam in rebus quotidianis quam in applicationibus specialibus per varias industrias, ut soleis calceorum, stragulis spumae mollis, lapidibus yogae, tabulis natatoriis, substratis pavimenti, et cetera.

2. Quae sunt limitationes spumarum EVA traditarum?

Multi putant spumam EVA esse perfectam coniunctionem testae durae et testae mollis. Attamen usus spumae EVA quodammodo limitatur propter eius resistentiam senescenti, resistentiam flexionis, elasticitatem, et resistentiam abrasionis insufficientem. Incrementum ETPU annis proximis et comparatio exemplorum etiam efficit ut calcei spumati EVA duritiem minorem, resilientiam maiorem, deformationem compressionis humilem, et alias proprietates novas habere debeant.

Praeterea, provocationes ambientales et valetudinis productionis spumae EVA.

Spumae EVA, quae hodie in foro praebentur, methodo spumationis chemicae praeparantur et praecipue ad res ut calceamenta, stragula, et similia, quae cum corporibus humanis directe in contactu sunt, adhibentur. Attamen spuma EVA, hac methodo et processu praeparata, varia problemata tutelae ambitus et valetudinis habet, et praesertim substantiae noxiae (praesertim formamidum) ab interioribus producti per longum tempus continenter separantur.